steam engine

Constructed by myself to the model of a Blanc-Misseron tramway

engine of the former Tramways de la Sarthe (France)

Powered by a 2-cylinder Stoker steam engine from a French 141 R war locomotive made in the USA

Boiler built in 1995 by Dupuis in Mönchengladbach to plans by Andreas

Scholz. Water capacity 49 l, Steam production about 40 l/h, Pressure 10

bars, heating surface about 1 m².

More about this locomotive

Weight of engine: 1280 kg

Service weight:t 1450 kg

Overall length: 2,50 m

Constructed from 1998 to 2000

Official approval by technical survey and delivery of permit: 21.05.2001

photo: preparing for service at Neckarbischofsheim on June 3rd, 2001

O&K 9798

1939

weight 2,5 t

original monocylinder 12 HP diesel engine

3 gears with a conical clutch each, operated by a vertical spindle

bought from Sandwerke Kiener in Goldshöfe (near Ellwangen/J.) in

1991

The completely corrugated gearbox had to be set free, the motor needed tricky repair after a previous freezing damage. The original exhaust pipe was extended upwards and fitted with a protection grid.

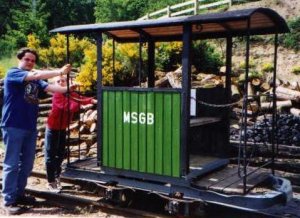

Gmeinder 4460

1948, without electric equipment

Gewicht 3,2 t

original monocylinder 12 HP Kaelble diesel engine

bought from Blattert tileworks in Murr/M. in 1983 as the first MSGB loco

This engine had had a very rough service on a straight to-and-fro line

so that the wheels were worn out by 1 cm and had become rather double

flange. They had to be reprofiled on a leathe in 1984 for running properly

over my points. On the same occasion, the loco got a simple roof and an

upward exhaust pipe. Now the motor needs complete re-sealing and the

pinions of the chain drives should be replaced

Diema 833 (Type DL 12)

1937 ( rather modified)

weight 2 t

air- cooled 20 HP 2-clinder Deutz engine (replacement)

3 gears with a multidisc clutch each, operated by horizontal steering

wheel

Full 12 V electric equipment

exchanged in 1998 for an O&K ruin from IG Feldbahn Franken and rebuilt

to its original appearance in 1999: The couterweight box was removed and

the rear of the cabin put some 20 cm forward again.

1921

almost identic to No 9798, original engine, flat belt-drive of the ventilator, large spring-loaded buffers: The rods for commanding the 3re gear are missing.

The engine was exchanged by Bernard Bommert in 2005 for a Decauville mine tractor purchased in 1994 and working on his railway since then.

The history of this engine is unclear. It must have been delivered directly to France beacause all the instruction-plates are in French.

Covered goods van with brakeman's cabin type "G 10"

built in 1982

overall length: 2,40 m

The chassis of this van is a former dumper with a brake from the former Schorndof tileworks, the body with two sliding doors was made from old floor planks and iron from our old garden fence. The brakeman's cabin encloses the original brake. Originally this van served as a (mobile) shelter for gardening tools and was equipped with a lockable storage box (for small material and drinks, its top serving as a bench). Later I added two small seats on the brakeman's side. In 1998 the wooden planks had to be replaced and the chassis was spring-loaded. Stangely enough, this van is small children's favourite vehicle.

Flat lorry

built in 1983

overall length: 2,40 m

The chassis of this car comes from Schorndorf, too. It had no couplings and served in early MSGB times for gardening purposes: it was therefore fitted with a wooden planking and sometimes carried a water tank. On the arrival of the first loco I fitted two couplings cut from two other lorries and built the actual box with opening sides. As the bake spindle and its support it can easily be removed in order to use the chassis as an universal transporter. The bake is then operated by pulling on a wire. The lorry became spring-loaded in 1986 and the brake mecanism was imporved..

2 Passenger coaches type "Cie"

built in 1985 and 2001

overall length: 2,40 m

For building these coaches normal lorries were lenghtened to 2,40 m with keeping the axle distance of 700 mm.The bodies are built exclusively from scrap: Iron and pipes for the framework, and pieces of floor and wall panels for the sides and the inner roof. Two solid planks serve as benches for about 6 passengers. In 1998 the coaches were spring-loaded and equipped with a brake with a removable spindle.

Dumpers of a capacity of 0,5 m³ and 0,75m³

years of construction unknown

These dumpers come from different tileworks and are in poor to average condition. The second (from the right) worked in Möding where each lorry was fitted with a spring-assisted brake. So they coud be launched one by one on a long straight gradient down to the works. Here the brake was released for the dumping manoeuvres. A "train" of empty dumpers was then hauled uphill again by a winch for reloading.

Small "roundabout" dumper (0,5m³)

bought in 1986 from Grübele & Sons, Oppenweiler

After World War II Grübele had specialized in building water reserves

and big underground water tanks. These were often located in the woods

and were rather unaccessible, so concrete was mixed nearby and carried

. on the spot by this dumper. (At the time "Readymix" and concrete

pumps were unknown!) .

I appreciate this small rondabout dumper for work on the track, especially

for putting gravel: 1 load allows to fill the length of 2 sleepers.

Project 1 for 2009: Diesel-hydraulic Railcar

When building the boggies for a new 4-axle passenger coach I had the idea of motorising two of them in order to build a railcar. It will be 5 metres long and offer 12 to 14 seats.

Each boggie will be powered by a hydraulic motor with Duplex chain drives to the two axles. The hydraulic motors are operated by a pump-unit coupled to a three cylinder Kubota Diesel. All these items are taken from a dismantled cleaning machine

Project 2 for 2009: 4-axle passenger coach

As I sold the passenger coach to the Neckarbischofsheim Railway Club

in May 2008 I would like to rebuild another one to the same construction

principles, mainly a lowered middle part with wide doors for

passengers in wheelchair. The new coach will be lighter

for steam hauling, its running comfort will be better with springed

Diamond-type boggies. A brake system will enhance safety.

The aspect will be more "modern" so that the coach can also be used

together with the projected railcar.