More about the steam engine

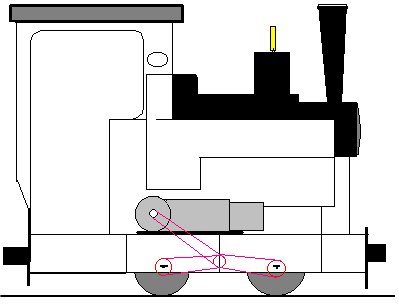

A long time before the arrival of electric tramways in urban areas there was a vast network of meter-gauge secondary railways in the French country. In town, the track often ran in the middle of the streets and outside the urban area alongside country roads. To avoid serious and often fatal injuries when (inattentive) pedestrians, bikers or horses came into contact with the moving parts of the engines, these were covered by lateral panels which could be removed for servicing. The model for this little steam engine is a partly panelled 0-6-0 Blanc-Misseron tramway-engine which worked for the "Tramways de la Sarthe" around Le Mans, well-known for its 24-hour motor races and "Rillettes". Whereas in the original only the outside gear of a normal loco was covered, a rather curious construction hides inside here:

A steam motor drives an intermediate shaft by a chain, from here two chain

drives act on the spring loaded driving axles. The motor is an horizontal

2-cylinder steam engine with a constant admission of 80%. A piston-type

reversing valve is fitted between the admission and exhaust tubes.

The motor is from one of the American 2-8-2 mixed traffic engines sent

to France during and after WWII and run by the SNCF as "141R".

It was fitted on the tender for driving the 'Stoker', an articulated screw

that allowed to convey coal from the tender directly into the firebox..

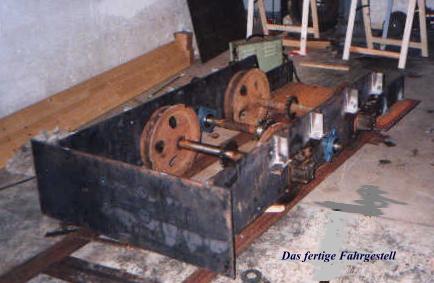

The frame is made from 8mm steel plates. The two side pieces together with the front and rear plate form a solid "box", the metal cabin floor and the lateral footplates assuring its rigidity. With a length of 2,50 m, an overall width of 1,00 m and a weight of 1280 kg the loco can be transported on a normal solid car trailer..

View of the nearly finished frame The rear plate and the footplates are missing. The right bearing of theintermediate shaft must be screwed to the frame, the transmission chains and the elements of the braking system are waiting their turn....

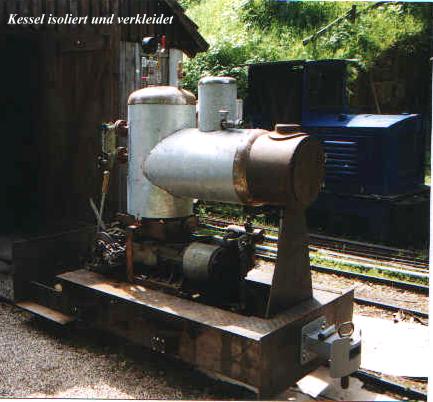

The boiler however is a "genuine" construction with

a wet firebox without stays, tubes and a smokebox by Dupuis in Mönchengladbach

to plans by narrow gauge enthusiast Andreas Scholz. It develops about

3,5KW at a pressure of 10 bar. As the boiler contains only 49 litres,

it is considered as "minor device" and needn't undergo biannual

pressure tests. It was built in 1995 and put into service in 2001.

The frame with the motor and boiler. There is only very

little space for the ashpan between the crankbox and the grate. The reversing

valve is visible on the left cylinder. I abandonned the idea of using

a disc from a Citroen 2CV in favour of a classical system with oak brake

blocks. The buffers are adjustable in height....

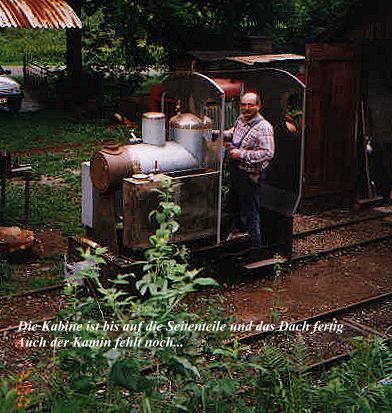

With the building of the cabin this "stacking" slowly turns

into a nice design:

The cabin is spacious enough for two people. Your back doesn't hurt after

a full day's service because all the cab fittings - the fire door included

- are within your reach.

In October 2001 the loco is set under pressure for the first time. The

chimmney wasn't ready yet, so an old pipe from a stove was used instead.

After two days of testing we dismantled the loco completely in order to paint the different parts and to carry out some modifications - certainly not the last ones!